Porton Biopharma Ltd (PBL)

Porton Biopharma Ltd, (PBL) wished to relocate both their existing Down Stream Process (DSP) and Fermentation units to a new facility within the existing PBL site. The relocation was part of addressing regulatory concerns and providing a flexible facility, whilst implementing current requirement and adapting to future requirements.

Relocating the DSP and Fermentation units into a purpose designed facility to allow improvements, collaborative working and operational efficiencies.

The facility was designed:

- In close proximity to other related units of circa 600m2 to accommodate scientist dedicated to developing and improving methods used in pharmaceutical manufacturing of life saving products

- As a stand-alone single storey building, it was designed to be capable of incorporating an additional storey to facilitate future expansion requirements with minimum impact.

- To reflect modern best practices in design of a fermentation suite with a range of bench-scale reactors and downstream processing suite for activities such as filtration and chromatography.

Austin worked with the two user group representatives and developed: a solution of the proposed requirements with the required material and personnel flows; a layout for Down Stream Process and Fermentation units.

Each room was designed with finishes suitable for an Advisory Committee on Dangerous Pathogens (ACDP) Containment Level 2 (CL2) classified area and the cleaning regime requirements.

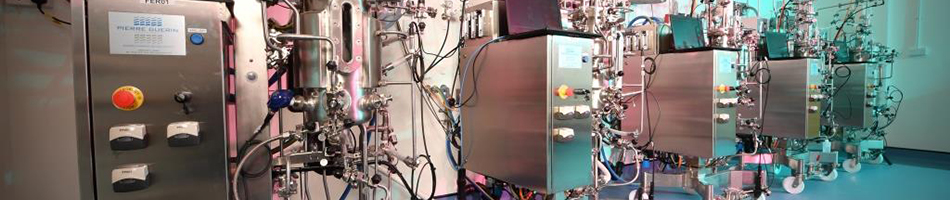

Six fermenters required steam, compressed air, chilled water, water, reverse osmosis water, nitrogen and oxygen. Distribution of these services as well as all branch valves were located in the service corridor to allow pipe work in the fermenter room to be kept to a minimum.

Chilled water for space cooling and process cooling was expanded from a site-wide system. Hydraulic separation was achieved via a plate heat exchanger. Space cooling and process cooling required different temperatures and this was provided by two pumped circuits.

Steam for space heating and process heating was also expanded from a site-wide system. Heat was transferred to an LTHW system via a plate heat exchanger for space heating, whilst steam for process heating was supplied via a pressure reducing valve.

Due to the new building being downhill from the site condensate main, a condensate recovery unit was provided to pump the condensate out of the building.

The fermenter area was classified as a Class II. A pressure cascade was required whereby air flows from outer rooms, in to the Class II. This was achieved by statically balancing the ventilation system to provide 10 Pa steps between rooms.

The extract from the Class II was provided with HEPA filtration to filter out biologically hazardous material from the air.

The project was developed using Revit (BIM), to provide greater coordination and collaboration between the design and construction team; identifying clashes and risk mitigation throughout the design process, whilst reassuring a high level of certainty as the project progressed to construction.

Austin designed, procured, constructed and commissioned the facility to meet PBL’s stringent requirements.